Buying a FOBOT: What is a FOBOT and how to choose the right one for your optical fibre network?

Fibre 101 HypaConnect Optical Fibre - November 21, 2019

If you’re in or involved within the ICT industry, chances are you’ve heard the word FOBOT used before. You may have even recently specified or installed one in a fibre optic network.

This article will help you understand the best design considerations and product selection criteria for FOBOTs. This post will cover everything you need to know about FOBOT’s, the different types and functions of a FOBOT and which FOBOT is right for your needs.

In particular, this article will focus on the FOBOT requirements for the Enterprise market, where the speed of deployment, reliability and cost-effective solutions are paramount.

What is a FOBOT?

So, what does FOBOT even mean?

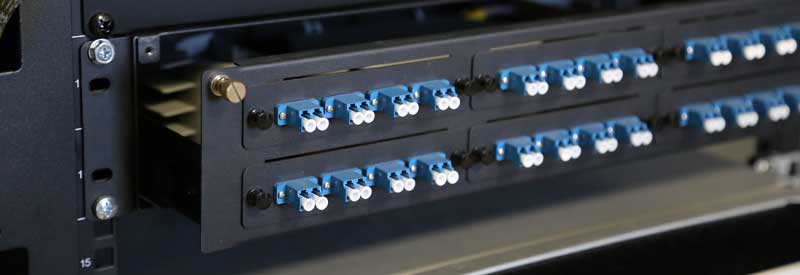

FOBOT is an abbreviation for ‘Fibre Optic Break Out Tray’, and this is what they can look like from the outside:

FOBOT’s can also be referred to as Fibre optic drawers, fibre optic enclosures, fibre optic patch panels or fibre optic subracks. Various names can be used, but basically, they perform the same function. They allow for splicing, termination and patching of optical ports to transmission equipment. Generally, a multifibre cable (either pre-terminated or un-terminated) is routed into the FOBOT, which is then ‘broken out’ or divided into individual fibres/ports.

These trays are responsible for organising and sheltering incoming fibres so that they are clearly and neatly displayed externally as a row of connectors. Generally, behind each of the optical fibre connectors, are pre-term cables or spliced on pigtails that are carrying optical signals.

Made from metal or plastic, the FOBOT provides stable and secure space for optical fibres at both the splice and patch points (we’ll cover this later).

Not only are FOBOTs designed to protect optical fibres, making connections stronger and more reliable, but custom made FOBOTS also allow for higher-density, meaning you can fit more fibre cable connections, without using more physical space.

What goes inside a FOBOT?

FOBOTs, as mentioned above, are protectors, organisers and distributors of optic fibre cables. When two different bare fibres are fused together, this is called splicing, which provides a permanent connection between the optical fibres. This requires a splice tray within the FOBOT to safely store this connection joint.

Patching refers to the interface/connector field and provides a physical connection/disconnection point. This is necessary when connecting to active equipment, as it provides a flexible interface for easily connecting and disconnecting services. The choice of connector is dependant on the connecting hardware interface, but will generally be SC/UPC, LC/UPC, ST for singlemode and multimode connections, or SC/APC or LC/APC for singlemode connections.

Generally, there are two types of FOBOT’s and functions they perform:

| Splice and Patch FOBOTs: | Patch only FOBOTs: |

|

|

Splice and patch FOBOT’s enables fibre optic cable to be cut to length and spliced onto fibre optic pigtails within the FOBOT. The splice joint and pigtails are stored in a splice tray within the FOBOT. The fibre optic pigtails are routed to the rear patching field of the FOBOT and present as a physical connection interface (LC, SC, etc.).

A patch only FOBOT is suitable for preterm multi-fibre optic cable assemblies, which are already connectorised cables. A breakout or riser cable will be measured to length and terminated with optic fibre connectors.

Therefore, a patch only solution removes the need for onsite splicing but requires the installer to know the specific length of the cables used, as they need to fit and connect within the FOBOTs.

What are the different types of FOBOTs?

There are a few different ways FOBOTS can be designed.

Fixed tray – no movable parts:

Fixed FOBOTS are cost-effective and sturdy but do not allow easy access to cabling.

Swing out FOBOTS allow the most access to cabling and reduce the amount of fibre cable movement. They generally have more features included and can also be customised.

The traditional slide FOBOT is easy to use and cost-effective while also being sturdy and accessible.

Another important consideration is understanding how the FOBOT needs to be mounted, as well as the port density and rack space available.

Most FOBOTs should provide standard 19” rack-mount brackets, which allow the FOBOT to mounted on the front or rear rails in a rack. Optional 21” mounting brackets are also available.

Generally, most FOBOTs are supplied in Rack Unit (RU) increments from 1RU to 4RU. 1RU and 2RU are the most common sizes and provide the right balance between density and usability.

Most 1RU FOBOTs should provide an LC connector port density of at least 24 to 48 fibre ports per RU.

What to consider when selecting a FOBOT?

There are a few things to consider when selecting your FOBOT. What is right for someone else may not be for you. Some things to consider are:

- Density required. How many cables and connectors will you be running through the FOBOT?

- What FOBOT type is most suitable for you in terms of access required and budget? Is it the fixed, swing or slide model?

- Will you be splicing fibre optic cables, or will you use a pre-terminated patch only solution?

- What type of rack are you mounting your FOBOT in? Will it be rear or front-mounted?

- Do you need singlemode or multimode solution?

- Does your environment require dust protection?

- What type of connector will you be using? E.g. LC, SC, etc.

Why use Warren & Brown Slide-out FOBOTs?

Warren & Brown have a well-built reputation in the ICT industry, being trusted to provide connectivity solutions to Australia’s largest networks. Thousands of Warren & Brown FOBOTS are used in data centres and telcos across the country and overseas.

The Warren & Brown slide-out FOBOTs have become industry favourites due to their high-quality design and manufacturing process. Their FOBOT solutions are easy-to-use and customised.

Other FOBOT accessories and products – patch cords, cable

Additional products to consider when looking at FOBOTS are front cable management attachments, patch cords and cables.

The front cable management attachment is designed to provide better cable management of patch cords within the rack, so they do not impede other connection ports.

There are various types of patch cords and optic fibre cables that will be relevant depending on your particular set-up.

There you have it! Your complete guide to FOBOTs. Now that you know what a FOBOT is, its use and the different model types, you’re ready to purchase your own or show off your newly found knowledge on-site or in the office!

If you’ve got any questions on which FOBOT or accessories are right for you, feel free to contact us at [email protected].

Swing out FOBOTs:

Swing out FOBOTs: Slide-out panels:

Slide-out panels: